A product recall is the withdrawal of a product from sale due to safety concerns, such as contamination, incorrect labelling or undeclared allergens. In the UK, food recalls are overseen by the Food Standards Agency (FSA), which requires food manufacturers to act quickly to protect public health.

Recalls are serious concerns for food manufacturers, as costs for dealing with one can often reach millions of pounds. This is before you factor in indirect costs caused by reputational damage and a loss of customer trust.

A single food recall can threaten the survival of an SME, and cause reputational damage to even the biggest brands. With over 200 food incidents occurring in 2023/24, the threat is very much real and businesses need to have the right systems in place for prevention and response.

What Is The Cost of a Food Product Recall?

When discussing the cost of a food recall, it’s important to consider that there are two different types of costs that can impact a business:

Direct costs: those needed to actually undertake and resolve a recall, like fees for communications, logistics and the manpower for handling a recall.

Indirect costs: those that occur as a result of the recall, usually after the recall itself and with a long-term impact, such as lost business and reputational damage.

While you can factor in the more tangible direct costs when risk assessing a potential food recall, it’s more difficult to do so for indirect costs, the scale of which might depend on the severity of the recall and/or your response to it.

Recent UK analyses suggest food recalls cost around £1 million in typical direct expenses, with many serious cases running up between £2.5 million and £5 million. Larger scale recalls can easily exceed £10 million once indirect costs are considered, especially when allergy or contamination risks are involved.

Direct Costs Include:

Financial Losses & Costs

The direct costs of a recall can quickly escalate with product withdrawal, stock write-offs, logistics and supplier disputes.

Regulator & Legal Action

Failure to act quickly or report accurately can result in FSA investigations, enforcement notices and prosecution.

Indirect Costs Include:

Brand Damage

Public recalls can erode trust in your brand due to negative press, social media backlash and potential retailer delisting.

Lost Confidence

Just one incident can drive customers toward competitors, especially if allergens or health risks are involved.

Causes Of Food Recalls In The UK

Food product recalls occur when there are concerns over the safety of a product, usually due to undeclared allergens, contamination or mislabelled packaging. The first step for food manufacturers looking to prevent recalls is understanding what these safety concerns can be and where they can occur in your production process.

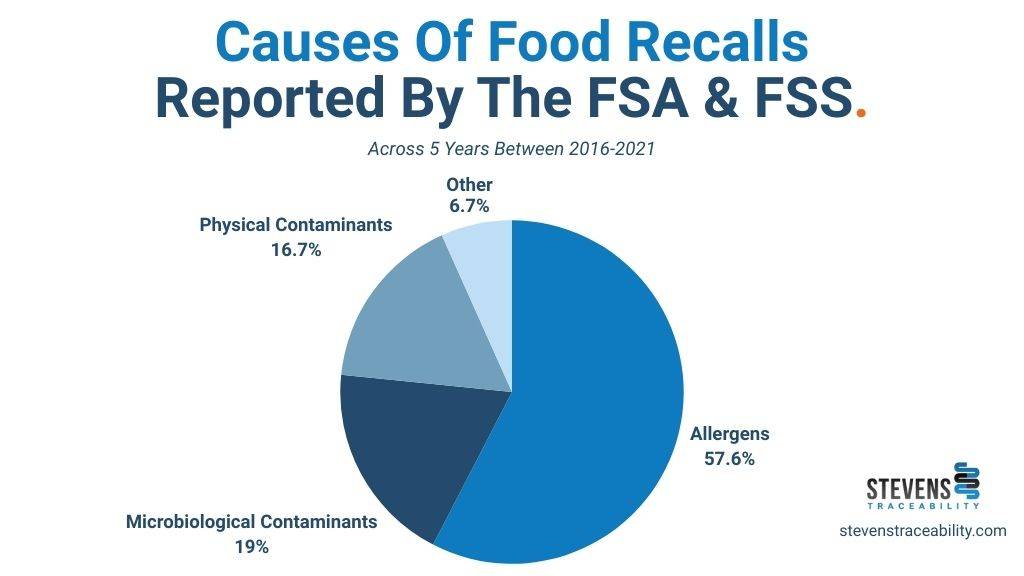

In recent years, mislabelled allergens and pathogen contamination have both been the most common causes of food recalls in the UK. A 2023 study of the causes of recalls over a 5 year period found that undeclared or mislabelled allergens caused 57.6% of recalls. Ingredients like milk, gluten, nuts, soya, eggs and mustard are frequent triggers.

It isn’t just allergens you need to worry about, though. Other common causes include:

- Microbiological or pathogen contaminants: bacteria like Salmonella, Listeria and E. coli can enter the supply chain in ready-to-eat foods, salads, dairy and other products through poor hygiene, handling and temperature control.

- Physical contamination: shards of plastic, metal or glass can end up in food products due to issues in the production line such as faulty machinery and a lack of thorough inspection equipment like metal detectors and x-ray inspection.

- Labelling errors: errors or issues in labelling the correct expiry, date or storage information for products can mislead consumers and lead to the unsafe consumption of food products.

How To Prevent Food Recalls

Most recalls are avoidable. Building stronger processes into your business can help you reduce food recall risk and protect your brand. By tightening controls and visibility across your supply chain and production process, you can drastically reduce the chance of being one of the dozens of UK businesses forced into a food product recall each year.

These five key controls form the foundation of effective food recall prevention, and can also help reduce the impact of a recall if one does occur:

1. Strengthen Supplier Management

Unsafe or mislabelled ingredients are often introduced upstream before they arrive on site. To combat this you should:

- Vet suppliers for compliance with the relevant food safety standards like BRCGS, ISO, and SALSA

- Audit the quality of raw material regularly

- Maintain centralised, digital records of the above checks

2. Improve Allergen and Label Control

Mislabelled allergens are the top cause of food recalls in the UK. You can prevent this type of incident by:

- Checking product labels against your recipes and formulations

- Using automated checks where possible to prevent human error

- Ensure cross-contamination risk is mapped at every stage of your production process

3. Tighten Hygiene and Food Safety Monitoring

Microbiological and pathogen contamination is another major cause for recalls. You can help prevent this with:

- Regular microbial testing of raw materials and finished products

- Monitoring of Critical Control Points (CCPs) in HACCP plans

- Document and review results digitally

4. Enhance Packaging and Distribution Oversight

Monitor every stage of your production process, and make sure your end-of-line stages aren't overlooked. Make sure to:

- Ensure tamper proof packaging integrity

- Monitor temperature control in cold chains

- Track logistics hand-offs and maintain digital proof of compliance

5. Train Staff and Build Recall Readiness

Systems and procedures are only as good as your team's ability to implement and follow them. You should:

- Regularly train staff on allergen handling, hygiene, and recall products

- Test recall scenarios annually

- Encourage a culture of reporting and proactive problem solving

The Biggest Challenges Manufacturers Face During A Recall

Despite the variety of issues that can trigger a recall, from allergen mislabelling to packaging failures, the challenges that manufacturers face in the aftermath are consistent. Understanding these pressure points is the first step to building a strategy that minimises both risk and speeds up recovery.

Challenge 1: Speed and Scope of Identification

The first hurdle food manufacturers face is simply knowing which products, batches, and customers are affected. Without clear traceability, recalls often become wider (and costlier) than they need to be as manufacturers can’t effectively identify specific batches affected, so err on the side of caution.

Challenge 2: Supplier and Ingredient Visibility

Many of the issues causing recalls can stem from suppliers ‘upstream’ - things like contaminated raw materials, incorrect specifications or missing documentation. When records on suppliers are fragmented, identifying the root cause of issues can sometimes take days, if not weeks.

Challenge 3: Labelling and Allergen Errors

Mislabelled products and undeclared allergens remain the number one cause of recalls in the UK. These errors can occur in gaps in the production process, and can be life-threatening for consumers.

Challenge 4: Regulatory Compliance (FSA, BRCGS etc.)

Navigating the recall process involves strict reporting, documentation, and communication with the Food Standards Agency and retailers. Many manufacturers underestimate the complexity and speed required to comply with the expectations of regulators.

Challenge 5: Brand and Customer Impact

Even when handled well, recalls can erode customer trust and can damage the relationships manufacturers have with retailers and partners. The reputational fallout and indirect costs often far outweigh the direct financial costs.

With recalls costing UK food businesses upwards of £1 million on average, these challenges can’t be ignored. The good news is that all of them can be tackled with the right traceability system. By centralising data, ensuring regular checks, and providing real-time visibility over your production process, digital traceability supports your recall prevention and response strategies.

How To Handle A Food Product Recall, Step-by-Step

Even the best run operations can face a product recall, and what matters most is how quickly and effectively you respond to it. The Food Standards Agency (FSA) requires manufacturers to follow a clear process, and every hour counts in protecting consumers and your brand.

As a result it’s important that your team know how to handle a product recall to ensure as decisive a response as possible.

Below is a typical response plan:

Please note we are not a regulator or legal body, and are only providing guidance and support towards compliance – we always recommend businesses refer to the FSA and relevant regulatory bodies for the most accurate and up-to-date guidance.

How Traceability Systems Improve Recall Response

While stressful and with high-stakes, recalls don’t need to be chaotic events. With the right systems and processes in place, food manufacturers can act quickly, confidently and in a way that protects both consumers and their brand.

Implementing a traceability system into your production process is a good way of achieving this. The Stevens Traceability System is designed to support business’s recall response strategies, helping you to build a strategy that is both proactive and resilient.

Here’s how the Stevens Traceability System supports you:

Speed of Action

Instant access to live production and batch records means you can quickly identify which products are affected. Our system removes the need for manual searching across paperwork or spreadsheets, helping you respond to recalls in hours instead of days.

Precision in Scope

With detailed batch traceability, the Stevens Traceability System lets you isolate specific lines or lots rather than pulling entire product ranges. This reduces the financial and operational impact, but also avoids unnecessary food waste.

Regulatory Confidence

The Stevens System allows you to generate digital reports at the click of a button, meaning you can deliver a complete digital audit trail in a matter of seconds when regulators ask for evidence.

Clearer Communication

Accurate, centralised data from the system makes it easier to create recall notices for retailers, distributors and consumers. Consistency across channels helps preserve trust at a critical time.

Practical Next Steps For Food Manufacturers

Every food business can strengthen it's recall readiness. The key is implementing the right systems in your production process, and building your team's confidence in the recall plan before a crisis hits.

You can take the following three steps today:

- Review Your Recall Plan

Does your business have a clear, documented process for handling a recall? Make sure you have one in place if not, read our example plan. - Estimate The Cost Of A Recall

Many businesses underestimate the financial and reputational impact until it's too late. Establish an estimated cost based on your operations so you're not caught out. - Explore Digital Traceability

The best way to improve your recall strategy is by using the right tools and systems. Book a demo of the Stevens Traceability System to see how batch-level traceability and digital reporting can improve your recall response.

Let's Help You Get Ahead Of Food Recalls With Digital Traceability.

Our traceability solution is built for UK food manufacturers who are looking to improve their operations and recall strategies with:

- Full visibility of every batch and ingredient

- Rapid recall response

- Centralised electronic records for audits and compliance

- Allergen management controls and QA tools

If you'd like to know more about our traceability system, or would like to organise a quote or demo, complete the form and a member of our team will be in touch.

Free Traceability Assessment Tool.

This diagnostic tool will help determine your requirements and provide you with a report on what you need now from your traceability system.

Answer just 5 multiple choice questions and get a free report to download for you to print or share digitally with your team.